+86-15267462807

+86-15267462807

Bubble Tube Diffusers represent a sophisticated technology in the realm of water treatment, combining precision design principles with efficient operational mechanisms. Understanding the intricacies of their design and operational science is essential to appreciate their role in maximizing oxygen transfer to water.

1. Diffuser Material and Construction:

Bubble Tube Diffusers are typically constructed from high-quality materials such as EPDM (ethylene propylene diene monomer) or silicone. These materials are chosen for their durability, resistance to corrosion, and flexibility.

The diffuser membrane, responsible for bubble generation, is designed to withstand the mechanical stresses associated with bubble formation and release.

2. Bubble Generation Mechanism:

The heart of the Bubble Tube Diffuser lies in its ability to generate fine bubbles. This is achieved through a carefully designed porous membrane that allows the controlled release of air in the form of tiny bubbles.

Micro-perforations or fine slits on the membrane ensure the formation of bubbles with a high surface area, optimizing the oxygen transfer efficiency.

3. Distribution System:

Efficient distribution of bubbles is crucial. The design incorporates features such as evenly spaced perforations or slits along the length of the diffuser, ensuring uniform bubble release.

The distribution system prevents the concentration of bubbles in specific areas, promoting consistent aeration throughout the water column.

4. Bubble Size Control:

The design principles include mechanisms to control the size of the bubbles generated. Smaller bubbles offer a larger surface area for gas exchange, enhancing oxygen transfer efficiency.

By fine-tuning the membrane design and perforation size, Bubble Tube Diffusers can produce bubbles of optimal size for maximum oxygen dissolution.

1. Air Supply System:

A reliable air supply system is integrated, providing a consistent flow of air to the diffuser. This system can be customized based on the specific requirements of the water treatment application.

Pressure and flow control mechanisms ensure the diffuser operates within optimal parameters, adapting to variations in treatment demands.

2. Controlled Release of Air:

Operational mechanisms ensure the controlled release of air through the diffuser membrane. This controlled release prevents the formation of large bubbles, which might rise too quickly without sufficient oxygen transfer.

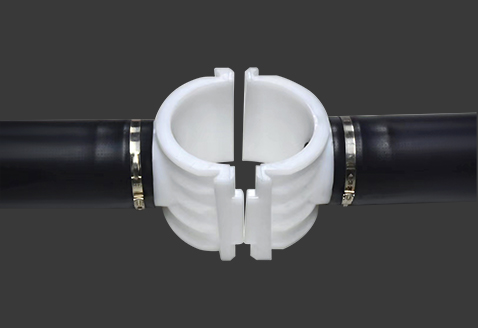

3. Integration with Aeration Grids or Pipes:

Bubble Tube Diffusers are often integrated into aeration grids or piping systems. The design allows for easy installation and ensures that the diffusers are strategically placed for maximum aeration efficiency.

4. Monitoring and Adjustment:

Advanced systems may include monitoring and adjustment capabilities, allowing operators to fine-tune the aeration process based on real-time conditions. This adaptability contributes to the overall efficiency of the water treatment system.

The science behind Bubble Tube Diffusers is geared towards maximizing the efficiency of oxygen transfer in water treatment. By combining precise design principles with advanced operational mechanisms, these diffusers ensure that the generated fine bubbles effectively dissolve oxygen into the water, promoting healthier aquatic environments and enhancing the overall success of water treatment processes.