+86-15267462807

+86-15267462807

According to traditional biological denitrification theory, the denitrification pathway generally includes two stages: nitrification and denitrification. The two processes of nitrification and denitrification need to be carried out in two isolated reactors, or in the same reactor with alternating anoxic and aerobic environments in time or space; in fact, in the earlier period, in some activated sludge processes without obvious anoxic and anaerobic stages, people have repeatedly observed the phenomenon of non-assimilated nitrogen loss, and the disappearance of nitrogen has also been observed many times in aeration systems. In these treatment systems, nitrification and denitrification reactions often occur under the same treatment conditions and in the same treatment space. Therefore, these phenomena are called simultaneous nitrification/denitrification (SND).

Synchronous nitrification and denitrification technology (SND) is to produce nitrification, denitrification and carbon removal reactions in the same reactor at the same time. It breaks through the traditional view that nitrification and denitrification cannot occur at the same time, especially under aerobic conditions, denitrification can also occur, making simultaneous nitrification and denitrification possible.

Nitrification consumes alkalinity, and denitrification produces alkalinity. Therefore, SND can effectively maintain the pH value in the reactor stable, without acid-base neutralization and external carbon source; save reactor volume, shorten reaction time, and reduce the floating of sludge in the secondary sedimentation tank by reducing the concentration of nitrate nitrogen. Therefore, SND has become a research hotspot for biological denitrification. Regarding the feasibility of SND biological denitrification, there are currently three main views from different perspectives:

Macro-environmental perspective: This view believes that a completely uniform mixing state does not exist, and uneven DO distribution in the reactor can form aerobic, anoxic, and anaerobic areas. Denitrification can occur under anoxic/anaerobic conditions in the same bioreactor. SND can be achieved by combining organic matter removal and ammonia nitrogen nitrification in the aerobic environment of the section.

Microenvironment perspective: This view holds that the anoxic microenvironment in the microbial flocs is the main cause of SND, that is, due to the diffusion (transfer) limitation of oxygen, there is a dissolved oxygen gradient in the microbial flocs, thus forming a microenvironment that is conducive to simultaneous nitrification and denitrification.

Biological perspective: This view holds that the existence of special microbial populations is considered to be the main cause of SND. Some nitrifying bacteria can perform denitrification in addition to normal nitrification. Dutch scholars have isolated pantotrophic sulfur cocci that can perform both aerobic nitrification and aerobic denitrification. Some bacteria cooperate with each other to perform sequential reactions to convert ammonia into nitrogen gas, which makes it possible to complete biological denitrification in the same reactor under the same conditions.

At present, there are many microbiological studies and explanations on biological denitrification, but they are not perfect, and the understanding of the SND phenomenon is still under development and exploration. The microenvironment theory is generally accepted. Due to the existence of dissolved oxygen gradient, the dissolved oxygen concentration on the outer surface of microbial flocs or biofilms is high, mainly aerobic nitrifying bacteria and ammonifying bacteria; deep inside, oxygen transfer is blocked and a large amount of external dissolved oxygen is consumed, resulting in anoxic zones, where denitrifying bacteria are the dominant species, which can lead to the occurrence of simultaneous nitrification and denitrification. This theory explains the problem of the coexistence of different strains in the same reactor, but there is also a defect, namely the problem of organic carbon sources. Organic carbon sources are both electron donors for heterotrophic denitrification and inhibitors of the nitrification process. When the organic carbon source in the sewage passes through the aerobic layer, it is first oxidized by aerobic oxidation. The denitrifying bacteria in the anoxic zone cannot obtain electron donors, which reduces the denitrification rate and may affect the denitrification efficiency of SND. Therefore, the mechanism of simultaneous nitrification and denitrification still needs to be further improved.

MBBR is a new type of efficient reactor that combines the suspended growth activated sludge method and the attached growth biofilm method. The basic design principle is to directly add the suspended filler with a specific gravity close to water and can be suspended in water into the reaction tank as an active carrier of microorganisms. The suspended filler can contact with sewage frequently and multiple times, and gradually grow a biofilm (film) on the surface of the filler, which strengthens the mass transfer effect of pollutants, dissolved oxygen and biofilm, that is, MBBR is called "mobile biofilm". Based on the research on SND mechanism so far, combined with microenvironment and biological theory, the possible reaction mode of SND in MBBR biofilm is that aerobic ammonia oxidizing bacteria, nitrite oxidizing bacteria and aerobic denitrifying bacteria distributed in the aerobic layer of the biofilm cooperate with anaerobic ammonia oxidizing bacteria, autotrophic nitrite bacteria and denitrifying bacteria distributed in the biological anoxic layer, and finally achieve the purpose of denitrification.

MBBR relies on the aeration and water flow in the aeration tank to make the carrier in a fluidized state, thereby forming suspended activated sludge and attached biofilm, giving full play to the advantages of both attached and suspended phase organisms, not only providing macroscopic and microscopic aerobic and anaerobic environments, but also solving the DO and carbon source disputes between autotrophic nitrifiers, heterotrophic denitrifiers and heterotrophic bacteria. Therefore, MBBR can achieve the kinetic balance of the two processes of nitrification and denitrification, has very good conditions for simultaneous nitrification and denitrification, and can achieve MBBR simultaneous nitrification, denitrification and denitrification.

The key technology to achieve MBBR simultaneous nitrification and denitrification is to control the reaction kinetic balance of nitrification and denitrification in MBBR, solve the DO dispute between autotrophic nitrifiers and heterotrophic bacteria and the carbon source dispute between denitrifiers and heterotrophic bacteria, etc. Therefore, the main control factors are: carbon-nitrogen ratio, dissolved oxygen concentration, temperature and pH, etc.

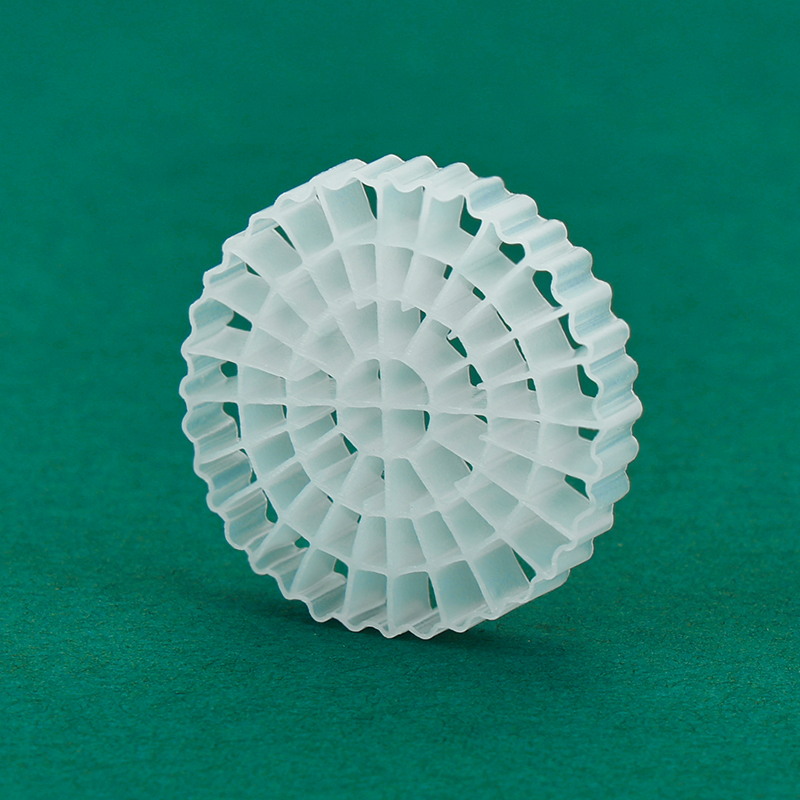

The technical key of MBBR method lies in biological fillers with a specific gravity close to that of water and easy to move freely with water under slight stirring. Usually, the fillers are made of polyethylene plastic. The shape of each carrier is a small cylinder with a diameter of 10mm and a height of 8mm. There are cross supports in the cylinder and protruding vertical fins on the outer wall. The hollow part of the filler accounts for 0.95 of the total volume, that is, in a container full of water and fillers, the volume of water in each filler is 95%. Taking into account the rotation of the filler and the total container volume, the filling ratio of the filler is defined as the proportion of the space occupied by the carrier. In order to achieve the best mixing effect, the maximum filling ratio of the filler is 0.7. Theoretically, the total specific surface area of the filler is defined according to the number of specific surface areas of biological carriers per unit volume, which is generally 700m2/m3. When the biofilm grows inside the carrier, the actual effective specific surface area is about 500m2/m3.

This type of biological filler is conducive to the attachment and growth of microorganisms on the inside of the filler, forming a relatively stable biofilm, and it is easy to form a fluidized state. When the pretreatment requirements are low or the sewage contains a large amount of fiber, such as when the primary sedimentation tank is not used in municipal sewage treatment or when treating papermaking wastewater containing a large amount of fiber, a biological filler with a smaller specific surface area and a larger size is used. When there is a good pretreatment or it is used for nitrification, a biological filler with a large specific surface area is used.

DO concentration is a major limiting factor affecting simultaneous nitrification and denitrification. By controlling the DO concentration, aerobic zones or anoxic zones can be formed in different parts of the biofilm, thus having the physical conditions for achieving simultaneous nitrification and denitrification.

Theoretically, when the DO concentration is too high, DO can penetrate into the biofilm, making it difficult to form anoxic zones inside, and a large amount of ammonia nitrogen is oxidized to nitrate and nitrite, so that the effluent TN is still very high; on the contrary, if the DO concentration is very low, it will cause a large proportion of anaerobic zones inside the biofilm, and the denitrification capacity of the biofilm will be enhanced (the concentrations of nitrate and nitrite in the effluent are very low), but due to insufficient DO supply, the nitrification effect of the MBBR process decreases, causing the effluent ammonia nitrogen concentration to increase, thereby causing the effluent TN to increase, affecting the final treatment effect.

Through research, an optimal DO value for MBBR treatment of urban domestic sewage was finally obtained: when the DO concentration is above 2 mg/L, DO has little effect on the nitrification effect of MBBR, the removal rate of ammonia nitrogen can reach 97%-99%, and the effluent ammonia nitrogen can be kept below 1.0 mg/L; when the DO concentration is around 1.0 mg/L, the removal rate of ammonia nitrogen is around 84%, and the effluent ammonia nitrogen concentration has increased significantly. In addition, the DO in the aeration tank should not be too high. Too high dissolved oxygen can cause the organic pollutants to decompose too quickly, resulting in a lack of nutrition for microorganisms, and the activated sludge is prone to aging and loose structure. In addition, too high DO will consume too much energy, which is also economically unsuitable.