+86-15267462807

+86-15267462807

In the water treatment process, the sedimentation tank is one of the key links. Its purpose is to remove suspended particles through gravity. In order to improve the efficiency and treatment capacity of sedimentation tanks, more and more water treatment facilities have adopted Tube Settler technology in recent years. This article will explore in detail how the Tube Settler works and how the performance of the settling tank can be optimized through this technology.

How Tube Settler Works

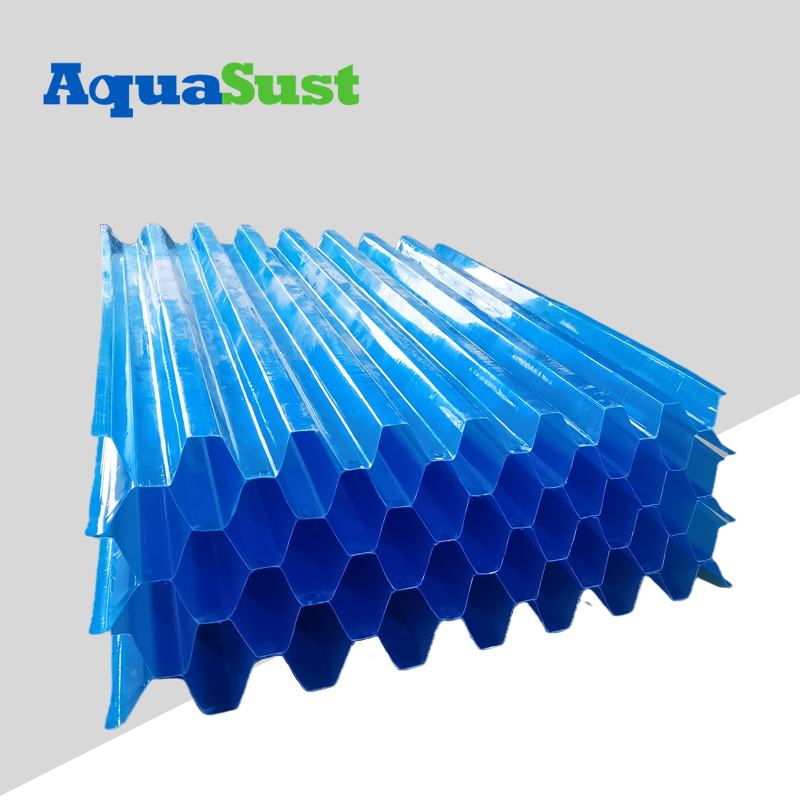

Tube Settler consists of a series of tubes or grooved plates placed at an angle and usually made into a hexagonal or rectangular shape. When the water flow containing suspended particles passes through these inclined pipes, the particles slide down the pipe walls under the action of gravity and settle to the bottom of the sedimentation tank. In this way, clean water can be collected at the top, thereby accelerating the settling process of suspended solids and improving treatment efficiency.

Optimizing sedimentation tank performance

1. Increase processing capacity

By installing a Tube Settler, the treatment capacity of your water treatment facility can be significantly increased. Since the Tube Settler can speed up the sedimentation process, the original sedimentation tank can handle more water flow. In the same space, using Tube Settler can improve processing efficiency by more than 50%.

2. Improve water quality

The Tube Settler removes fine particles more efficiently, so the effluent contains less suspended solids. This is very beneficial for subsequent filtration or other treatment steps, because lower suspended solids content can reduce clogging and wear of the filter material and extend the service life of the equipment.

3. Reduce the use of chemicals

With Tube Settler, the same or better treatment results can be achieved at lower chemical flocculant dosages. Due to the improvement of physical sedimentation efficiency, the reliance on flocculants can be reduced, thereby reducing chemical treatment costs and reducing chemical residues.

4. Reduce maintenance costs

Since the design of the Tube Settler makes it easier to concentrate and remove suspended solids, cleaning and maintenance of the sedimentation tank becomes simpler and more economical. Maintenance frequency and labor required for maintenance are reduced, thereby reducing long-term operating costs.

In conclusion

Tube Settler technology is an effective way to optimize the performance of settling tanks in water treatment facilities. Not only does it improve treatment efficiency and water quality, it also reduces operating and maintenance costs. For businesses looking to build or upgrade their water treatment facilities, investing in Tube Settler technology is a smart choice to increase competitiveness and sustainability. With proper design and installation, Tube Settler can bring long-term benefits to water treatment projects.