+86-15267462807

+86-15267462807

MBBR Bio Filter Media and activated sludge are two commonly used water treatment solutions, each with its own strengths and advantages.

Efficiency: MBBR Bio Filter Media offers high treatment efficiency due to its large surface area and the formation of a biofilm on the plastic carriers. The biofilm allows for effective biological degradation of organic matter and nutrient removal.

Footprint: MBBR Bio Filter Media requires a smaller footprint compared to activated sludge systems. It is particularly beneficial for applications where space is limited.

Flexibility: MBBR systems are flexible and can be easily expanded or modified to accommodate changes in wastewater flow and composition.

Robustness: MBBR systems are known for their robustness and ability to handle shock loads and variations in wastewater quality.

Operational simplicity: MBBR systems are relatively simple to operate and require less operator intervention and maintenance compared to activated sludge systems.

Nutrient Removal: Activated sludge systems are effective in achieving high-level nutrient removal, especially nitrogen and phosphorus, through proper process control and the addition of chemicals.

Sludge Production: Activated sludge systems typically generate more sludge compared to MBBR systems, which may require additional handling and disposal considerations.

Process Control: Activated sludge systems offer more precise process control and allow for adjustments in aeration and sludge recycling rates to optimize treatment performance.

Settling Characteristics: Activated sludge systems produce settleable sludge, which can be easily separated from the treated water through clarification and settling processes.

Treatment Performance: MBBR Bio Filter Media excels in the removal of organic matter and can achieve high levels of biological degradation. It provides efficient treatment for various pollutants commonly found in wastewater, including BOD (biochemical oxygen demand) and COD (chemical oxygen demand). Activated sludge systems, on the other hand, offer superior nutrient removal capabilities, particularly for nitrogen and phosphorus compounds. By adjusting the process control parameters and adding chemicals, activated sludge systems can achieve stringent nutrient removal requirements.

Space and Footprint: One of the significant advantages of MBBR Bio Filter Media is its compact design and smaller footprint compared to activated sludge systems. MBBR systems utilize plastic carriers with high surface area-to-volume ratios, allowing for a higher biomass concentration within a smaller tank volume. This makes MBBR systems ideal for applications where space is limited, such as retrofitting existing treatment plants or implementing decentralized treatment systems. Activated sludge systems typically require larger tank volumes due to the settling and clarifying processes, making them more suitable for larger treatment facilities with ample space.

Operational Complexity: MBBR Bio Filter Media systems are generally simpler to operate and require less operator intervention compared to activated sludge systems. MBBR systems are less sensitive to hydraulic and organic load fluctuations, making them more forgiving in terms of process control. On the other hand, activated sludge systems require more precise control of aeration, sludge recycling, and chemical dosing to maintain optimal performance. This may involve more complex monitoring and control mechanisms, as well as regular laboratory analysis for process optimization.

Sludge Production and Management: MBBR Bio Filter Media systems typically generate less sludge compared to activated sludge systems. This can be advantageous in terms of sludge handling and disposal, reducing the associated costs and environmental impact. Activated sludge systems produce more settleable sludge, which requires additional processes such as clarification, settling, and sludge dewatering for proper sludge management.

Flexibility and Scalability: MBBR Bio Filter Media systems offer excellent flexibility and scalability. They can be easily expanded or modified to accommodate changes in wastewater flow rates, pollutant loads, or treatment requirements. This adaptability makes MBBR systems suitable for both small-scale and large-scale applications. Activated sludge systems can also be flexible, but their modifications may involve more complex engineering and adjustments to hydraulic and aeration configurations.

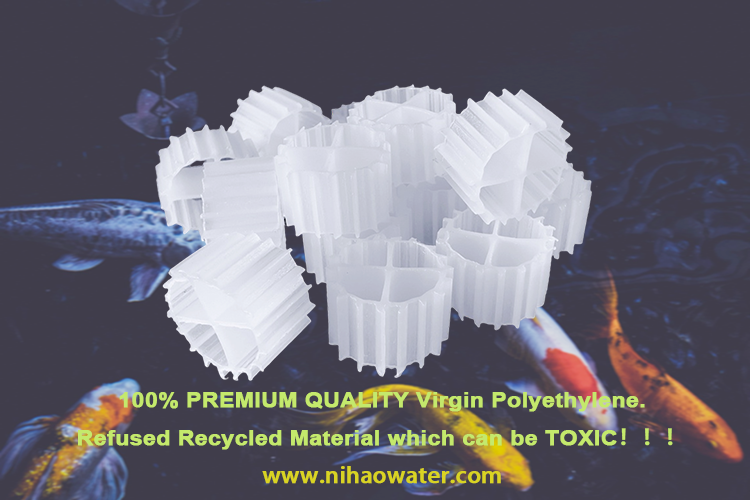

Hangzhou NIHAO Environmental Tech Co., Ltd is leading manufacturer and factory specializing in the production and sales of Plastic Products for the water treatment industry. We take pride in offering a wide range of high-quality products designed to meet the evolving needs of the water treatment sector such as MBBR Bio Filter Media, Tube settler Clarifier, Bio Block Filter media, MB Membrane Bio-Reactor, Disc Bubble Diffuser, Bubble Tube Diffuser, Spiral Mixing Aerator, Random Tower packing, Sludge Dewatering Machine and Water treatment plant and so on.

We are committed to driving innovation and delivering products that contribute to the advancement of the water treatment industry. With our extensive product range, we aim to be your trusted partner in meeting your water treatment challenges.