+86-15267462807

+86-15267462807

According to the shallow tank theory, under the condition of a fixed effective volume of the sedimentation tank, the larger the surface area of the tank, the higher the sedimentation efficiency, independent of the sedimentation time. The shallower the tank, the shorter the sedimentation time. In a tube settler, the sedimentation zone is divided into thin layers by a series of parallel inclined plates or tubes, embodying the shallow tank principle. The characteristics of tube settlers with inclined plates or tubes are as follows:

1. Utilization of Laminar Flow Principle: Water flows between the plates or within the tubes, where the hydraulic radius is small, resulting in a low Reynolds number. Generally, the Reynolds number (Re) is around 200, indicating laminar flow, which is highly favorable for sedimentation. The Froude number of the flow within the tubes is approximately 1×10⁻³ to 1×10⁻⁴, indicating a stable flow state.

2. Increased Surface Area: The sedimentation area is increased, improving the efficiency of the sedimentation tank. However, due to the specific arrangement of the inclined plates, water inlet/outlet conditions, and internal flow patterns, the actual treatment capacity cannot reach the theoretical multiple. The ratio of the actual sedimentation efficiency to the theoretical sedimentation efficiency is known as the effective coefficient.

3. Shortened Particle Settling Distance: The settling distance of particles is reduced, significantly shortening the sedimentation time.

4. Re-flocculation of Particles: Flocculent particles re-flocculate within the inclined plates or tubes, promoting particle growth and further improving sedimentation efficiency.

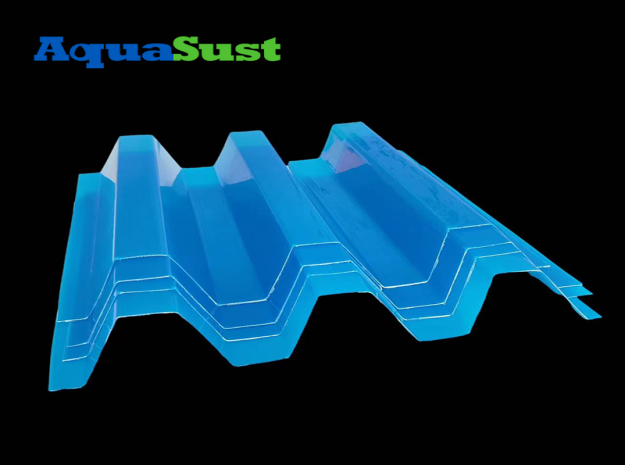

The structure of inclined tube or plate settlers is similar to that of conventional sedimentation tanks, comprising an inlet, sedimentation zone, outlet, and sludge collection zone. However, in the sedimentation zone, many inclined tubes or plates are installed. Figure 1 shows the typical structure of a tube settler.

In inclined plate and tube settlers, the flow direction of the water relative to the inclined plates can be categorized into three types: upward flow, downward flow, and horizontal flow, as shown in Figures 2 and 3.

1.Upward Flow (Countercurrent Flow): The water flows upward through the inclined plates or tubes while sediment settles downward. Their flow directions are opposite, a configuration referred to as upward flow or countercurrent flow.

2.Downward Flow (Concurrent Flow): Water flows downward through the inclined plates or tubes in the same direction as the sediment, referred to as downward flow or concurrent flow.

3.Horizontal Flow (Cross Flow): The water flows horizontally through the plates, known as horizontal flow or cross flow, applicable only to inclined plates.

Currently, most water treatment plants, such as those in power stations, use upward flow and typically employ inclined tubes as components for tube settlers.

Water enters the sedimentation tank horizontally. The inlet zone often features perforated walls, slotted walls, or downward-flow inclined tube inlets to ensure uniform water distribution across the width of the tank. The design and requirements are similar to those of horizontal sedimentation tanks. To achieve uniform outflow from the inclined tubes in upward flow systems, a sufficient height of the water distribution zone below the tubes is necessary, ensuring the inlet velocity is kept between 0.02 and 0.05 m/s.

The angle between the inclined plates and the horizontal plane is called the inclination angle (α). A smaller α results in a lower critical settling velocity (u₀), improving the sedimentation effect. However, to ensure automatic sludge sliding and unobstructed sludge discharge, α should not be too small. For upward flow systems, α is typically not less than 55° to 60°. In downward flow systems, where sludge discharge is easier, α is generally not less than 30° to 40°.

To make the most efficient use of the available tank volume, inclined plates and tubes are designed in compact geometric shapes, such as square, rectangular, hexagonal, and corrugated forms. For ease of installation, multiple or even hundreds of inclined tubes are grouped into a single unit, which is installed in the sedimentation zone. The materials used for inclined plates and tubes should be lightweight, durable, non-toxic, and inexpensive. Common materials include honeycomb paper and thin plastic sheets. Honeycomb tubes can be made from impregnated paper and cured with phenolic resin, typically forming hexagons with an inner circle diameter of 25 mm. Plastic sheets, such as 0.4 mm thick rigid PVC, are often thermally molded.

The longer the inclined plates or tubes, the higher the sedimentation efficiency. However, overly long plates or tubes are challenging to manufacture and install, and further length increases yield diminishing returns in efficiency. If the plates or tubes are too short, the proportion of the inlet transition zone (the turbulent to laminar flow transition zone) increases, reducing the effective sedimentation zone. The transition zone in the inclined tubes is about 100-200 mm. Experience suggests that upward flow plates should be 0.8-1.0 m long, with a minimum of 0.5 m, while downward flow plates are around 2.5 m long. With constant cross-sectional flow speed, smaller spacing between the plates or tube diameters increases flow velocity and surface load, thus reducing the tank size. However, excessively small spacing or tube diameters can lead to manufacturing difficulties and blockages. In water treatment, upward flow settlers usually have a spacing or tube diameter of 50-150 mm, while downward flow plates have a spacing of around 35 mm.

To ensure uniform outflow from the inclined plates or tubes, the arrangement of the water collection devices is crucial. These devices consist of water collection branches and main channels. Collection branches can include perforated troughs, triangular weirs, thin weirs, and perforated pipes. The height from the inclined tube outlet to the collection hole (i.e., the clear water zone height) is related to the spacing between the collection branches and should meet the following formula:

h≥√3/2L

Where:

h is the height of the clear water zone (m),

L is the spacing between collection branches (m).

Typically, L is between 1.2 and 1.8 m, so h is between 1.0 and 1.5 m.

The water flow velocity between inclined plates is similar to the horizontal velocity in horizontal sedimentation tanks, usually ranging from 10 to 20 mm/s. When coagulation treatment is used, the settling velocity (u₀) is around 0.3 to 0.6 mm/s.