+86-15267462807

+86-15267462807

Water treatment filler is the core part of sewage biofilm treatment method, which directly affects the treatment effect, investment cost and operation cost. There are many types of water treatment fillers, which can be classified in different ways. The following are some of the main types of water treatment filler:

First, according to the form and installation mode classification

Representative types: honeycomb packing, corrugated plate packing. These fillers are mostly composed of glass fiber reinforced plastic, various thin plastic sheets, there are also ceramic honeycomb filler produced by direct sintering of clay.

Characteristics: stable structure, but the specific surface area is small, the amount of biofilm is small, the surface is smooth, the biofilm is easy to fall, and the cost is high.

Representative types: soft filler, semi-soft filler, flexible three-dimensional filler, combined filler and so on.

Characteristics: large theoretical surface area, high porosity, fast hanging film, not easy to block, and low cost, easy to assemble. However, when the concentration of wastewater is high or the suspended matter in water is large, the packing wire will be agglomerated, affecting the service life.

Representative types: stacked packing (such as Bauer ring, step ring, hollow ball, etc.), suspended packing (such as porous spherical suspended packing).

Characteristics: no need to fix and hang, just placed in the treatment equipment, easy to use, simple communication. Porous spherical suspended packing has the advantages of good oxygenation function, fast film hanging, long service life and so on.

Second, according to the material classification

Representative types: ceramic, coke, quartz sand, activated carbon, expanded silica-aluminate and so on.

Characteristics: usually have high stability and durability, but the adsorption capacity may vary according to the material.

Representative types: fillers made of polymer materials such as polystyrene, vinyl chloride, polypropylene, and so on.

Characteristics: usually have better adsorption capacity and biophilicity, but may be affected by temperature, pH and other environmental factors.

C. Classification according to function and application scenarios

Representative types: activated carbon filler, ion exchange resin filler, and so on.

Characteristics: strong adsorption capacity for organic matter and heavy metal ions in sewage, applicable to scenes requiring efficient removal of specific pollutants.

Representative types: soft filler, combined fiber filler, and so on.

Characteristics: Provide a surface for microorganisms to attach and grow, promote the formation and stabilization of biofilm, suitable for biofilm method of sewage treatment process.

Representative types: suspended filler, multi-surface hollow ball, etc..

Characteristics: play a supporting and dispersing role in the fluidized bed, promote gas-liquid mass transfer and biological reaction, applicable to fluidized bed sewage treatment process.

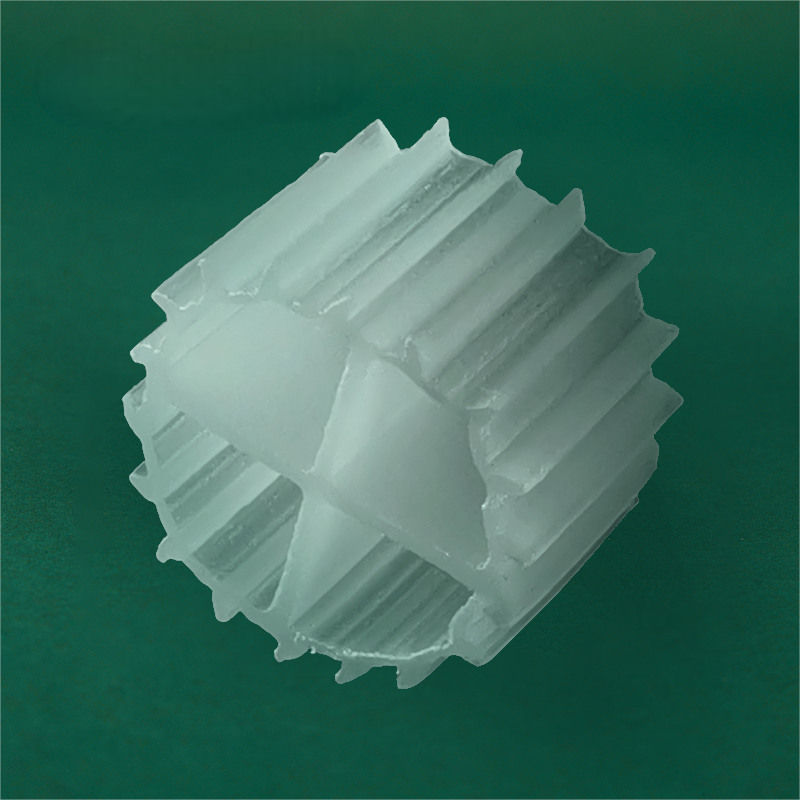

MBBR filler is a new type of biological active carrier and one of the biological fillers for sewage treatment, also known as fluidized bed filler. It adopts scientific formula, according to the different nature of sewage, integrates a variety of microelements in polymer material which is conducive to the rapid growth of microorganisms, and is modified and constructed by special technology.MBBR filler has the advantages of large surface area, good hydrophilicity, high biological activity, fast film, good treatment effect and long service life, etc. It adopts high-quality copolymer material, and is made of high quality polymer material. It adopts high-quality copolymer materials, special structural design (such as hollow filler structure for the inner and outer total of three layers of hollow circle, each circle has 1 prong, outside of 36 prongs), so that it can be suspended in the water during the operation process, the formation of fluidized bed.

In the MBBR process, sewage flows upward from the bottom at a certain speed, so that the filler is in the flow state, thus strengthening the mass transfer process and improving the treatment efficiency. At the same time, because the MBBR filler is constantly flowing, it can also prevent the blockage phenomenon and maintain the stable operation of the system. In addition, MBBR filler also has good impact load resistance, can resist the impact of fluctuations in incoming water quality, to ensure stable effluent water quality.

The main uses of MBBR packing include sewage treatment MBBR and biofilter process carrier, sewage upgrading project to improve the standard and quantity, water reuse, river management nitrogen and phosphorus removal, aquaculture nitrogen and decarbonization, as well as biological deodorization and so on. It is widely used in municipal, electric power, pharmaceutical, chemical, electroplating, metallurgy, medical, machinery, papermaking, printing and dyeing, food processing and other industries.