+86-15267462807

+86-15267462807

The tube settler in a water treatment plant usually refers to a device in an inclined tube settler or inclined tube settling tank.

Definition: A tubular settler, especially an inclined tube settler, is a sedimentation tank with inclined tubes in the settling zone. The water flow is separated into thin layers by the inclined tubes, and solid particles suspended in the water are separated by the principle of gravity settling, thereby achieving the purpose of purifying water quality.

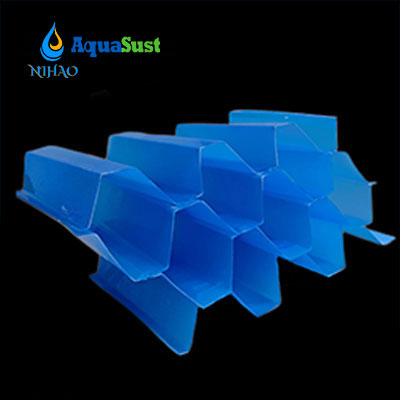

The inclined tube settler is usually composed of multiple parallel inclined tubes, and the shape of the inclined tubes is generally hexagonal, including regular hexagons and irregular hexagons, because the hexagonal structure can provide a larger sedimentation area and better water flow stability.

Due to the smaller hydraulic radius of the irregular hexagon compared to the regular hexagon, the corresponding Reynolds number is also smaller, the water flow is more stable, and the impact resistance is stronger. Under the same inscribed circle radius, the projected area can be increased by 22.5%

The inclined tube can be made of different materials, such as paper honeycomb, thin plastic board, etc. Paper honeycomb inclined tubes can be made of impregnated paper and cured with phenolic resin to form a regular hexagon, with a diameter of approximately 25mm for the inscribed circle. Plastic inclined pipes are generally made of PP, PVC material

PP material is superior to PVC material in terms of high temperature resistance, low temperature resistance, hardness, and compression and drop resistance

PP material performs well in a wider range of acidity and alkalinity, is easy to form, and is safe and non-toxic When purchasing, attention should be paid to its FDA certification

PVC material has a lower price and is easy to process Not applicable for the treatment of high-temperature water

Principle: When the density of suspended solid particles in water is higher than that of water, they will be subject to gravity and settle downwards. Inside the inclined pipe, due to the design of the pipeline, the water flow velocity is reduced, and solid particles have enough time to settle to the bottom of the pipe, while clean water flows out from the top of the pipe, achieving solid-liquid separation.

Structure: The inclined tube settler generally consists of four parts: inlet, settling zone, outlet, and mud collection zone. There are many parallel inclined pipes in the sedimentation zone, which divide the water flow into a series of thin layers, increase the sedimentation area, and improve the sedimentation efficiency.

characteristic:

By utilizing the principle of laminar flow, when the water flows in an inclined tube, the hydraulic radius is very small, the Reynolds number is low, and the water flow presents a laminar state, which is conducive to sedimentation.

Increased the area of the sedimentation tank and improved the sedimentation efficiency.

Shortened the distance of particle precipitation and greatly shortened the precipitation time.

The re aggregation of flocculent particles inside the inclined tube promotes further particle growth and improves sedimentation efficiency.

Application: Tubular precipitants are widely used in water treatment plants, especially in situations where efficient removal of suspended solid particles is required. For example, in a sewage treatment system, the sedimentation tank located after the biochemical reaction tank is called a secondary sedimentation tank, which is mainly used to separate sludge from water and clarify the effluent. At this point, a tubular settler is a good choice.

Advantages:

Compact structure and small footprint.

High sedimentation efficiency and good effluent quality.

Easy to operate and low maintenance cost.</>

Design parameters: When designing a tubular settler, parameters such as water flow velocity, inclined tube spacing, and inclination angle need to be considered. The selection of these parameters should be determined based on the actual water quality and treatment capacity.

Regular cleaning: In order to ensure the normal operation of the tubular settler, it is necessary to regularly clean the sediment to prevent blockage.

Maintenance: Regularly maintain the equipment, check whether the inclined pipes are intact, damaged or deformed, and replace damaged inclined pipes in a timely manner.