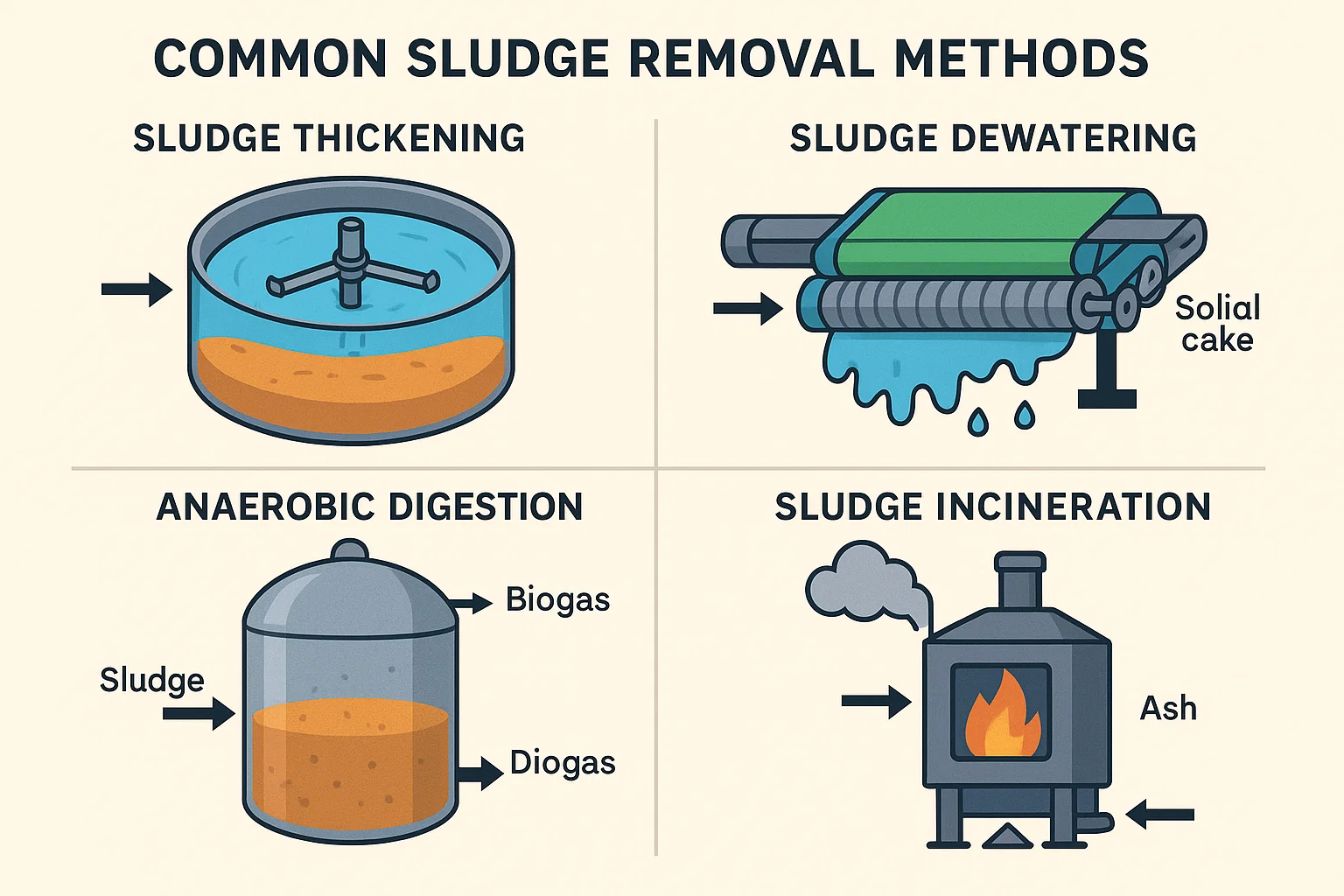

The belt press filter is mainly composed of a driving device, frame, press roller, upper filter belt, lower filter belt, filter belt tensioning device, filter belt cleaning device, and discharging device. gas control system. electrical control system. sludge is pumped into a dynamic (static) mixer, mixed with the anion (yang) ion flocculant solution added at the same time fully reacted, and then coagulated into a larger flocculent mass. The surface water of the material is separated into free water. The material is transported through the filter net of the first gravity pre-dewatering zone (or on the belt concentrator) and gravity is removed. Aftergravity dewatering, the fluidity of sludge becomes worse obviously, but it is still difficult to meet the requirement of sludge fluidity in the pressing dewatering section. Therefore, a wedge-shaped pre-pressing dewatering section is added between the pressing dewatering section and the gravity dewatering section of the sludge, and the sludge is dewatered by slight extrusion in this section. Removal of free water from its surface almost completely loses its fluidity, which ensures that sludge will not be extruded in the pressing dewatering section under normal conditions, creating conditions for smooth pressing dewatering.

English

English

عربى

عربى

Español

Español